Duke AERO is the premier aerospace engineering club at Duke, each year designing and building a high-powered rocket to compete at Spaceport America Cup. I joined my sophomore year and worked on Pitchfork, a rocket for SAC’s 10k foot SRAD (Student Researched and Developed) Motor category.

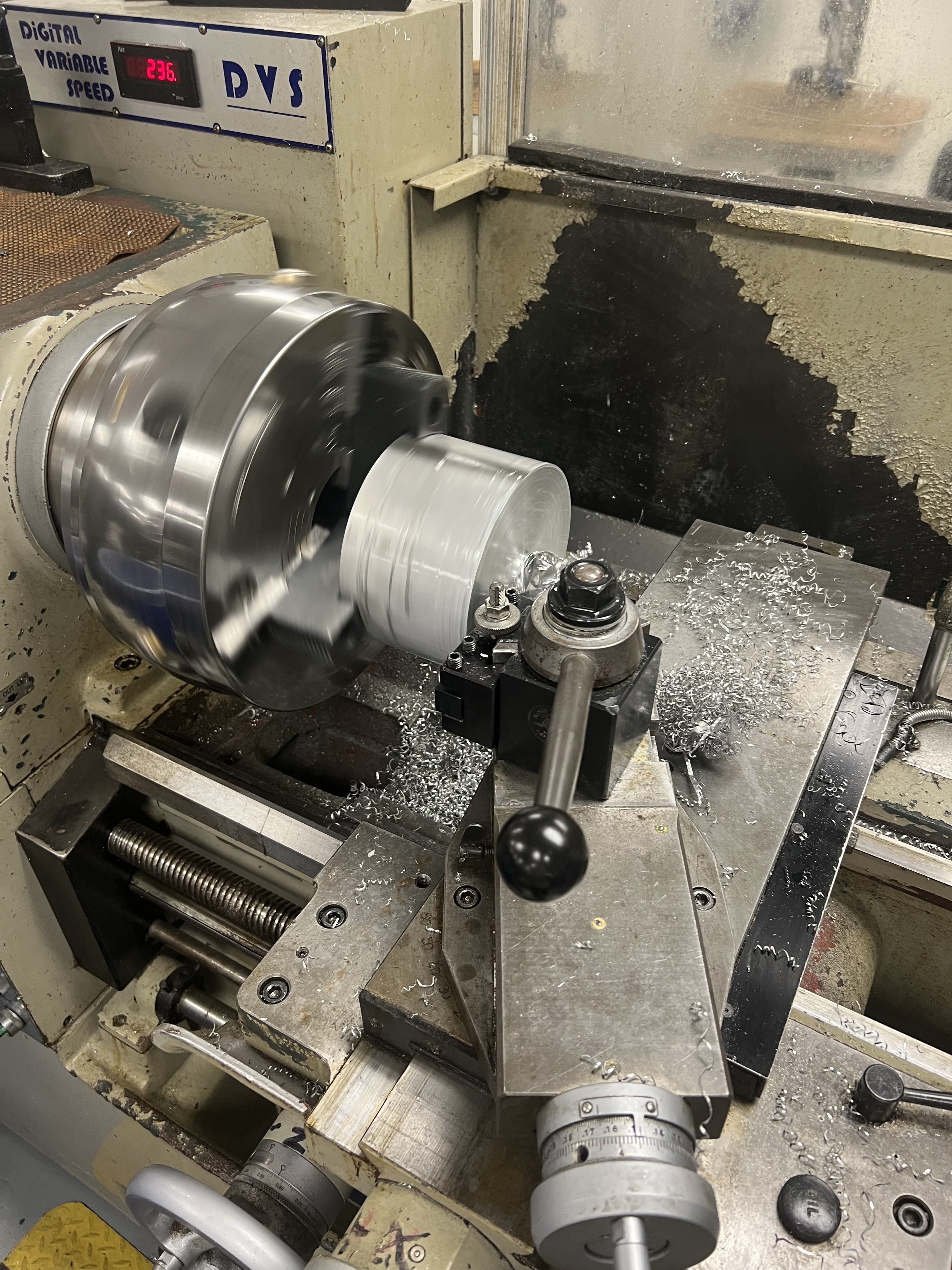

As a member of the Structures and Manufacturing Subteam, my work focused on the actual building of the rocket. I milled, turned, and tapped aluminum parts. I also gained a ton of experience in composite manufacture, working on wet and prepreg layups for body tubes and couplers. I even worked on novel “forged carbon” parts, using a combination of chopped tow and 3d printed molds.

Pictured Top and Middle is the lower half of the airbrake housing, which I turned on the lathe and milled on a Centroid CNC Mill. Manufacturing that piece of the rocket was a great learning experience, and also gave me a deep appreciation for the time that machining takes (~5 hours of operating a manual lathe for that step).

Pictured bottom is my team completing a tip-to-tip carbon fiber layup on our fins. We used composite fins and forged carbon fillets to attach the fins to the rocket. The fins were a composite “sandwich” with an internal PCB (to measure strain) printed on G10 fiberglass. The layers were as follows (CF G10 CF G10-Core CF G10-PCB CF). On the night pictured we unmounted the fins after a failed first attempt, remounted, and completed the tip-to-tip. This turned out to be a just under twelve-hour work session, but I can say that it was well worth it. Even after a catastrophic flight event during our launch at Spaceport that summer we recovered the power section of our rocket with the fins fully intact.

At Spaceport in Las Cruces, we received the Jim Furfaro Award for Technical Excellence, in recognition of our team achieving the best design and build of 150 teams. Despite a less than nominal flight, we left New Mexico winners.

I am excited to continue my work with Duke Aero this coming year, as we design and build to compete in the 30k SRAD category this coming year. I plan to continue my work with the Structures and Manufacturing Subteam, hoping to focus on developing my skills in Finite Element Analysis.